ION-X®

Subatmospheric Gas Storage and Purification

Product Platforms

ION-X®

The new way to store and deliver hazardous dopant gases

The global semiconductor industry trusts ION-X® subatmospheric gas delivery systems to deliver critical, yet hazardous dopant gases for advanced processing steps such as ion implantation.

The industry’s first MOF-based subatmospheric solution for dopant gas storage and delivery

As semiconductor devices advance, so must the technology used to enable them. ION-X® is a sub-atmospheric gas delivery system specifically designed for ion implantation, and the first commercial product that uses Metal-Organic Framework (MOF) materials.

MOFs can selectively adsorb, store and deliver ultra-high purity gases at sub-atmospheric pressures, offering performance advantages over traditional carbon-based adsorbent technology.

Cylinder performance

- ION-X® Subatmospheric Gas System (SAGS-1) is NFPA-rated, not only delivering but storing hazardous dopant gases subatmospherically

- ION-X® systems use DOT-rated high-pressure cylinders and valves, not welded cylinders, providing a 4x higher burst pressure rating

- Extensive testing programs have verified the integrity of the ION-X® system package (including OEMs and leading 300 mm fabs)

- There are no mechanical components on the package (other than state-of the art Ceodeux tied-diaphragm valves) which minimize residual risk of failure

- The MOF adsorbents used in ION-X® systems are stable and robust, so there is no degradation or decomposition over the life of the cylinder

ION-X® MOFs were specifically designed and extensively tested for their dopant gas compatibility, stability, and delivery performance.

Stability

MOFs are precisely designed to be 100% stable towards dopant gases

When designing a MOF, selecting the specific building blocks will define the physical and chemical properties of adsorbent material.

With an almost infinite number of metal node to organic linker combinations, MOFs can be designed to intentionally react with target gases, selectively adsorb a specific molecule, participate in chemical reactions, or passively condense gases in their pores.

Leveraging our data universe, Numat screened over 100,000 potential MOFs to determine the highest performing materials for storage and delivery of arsine, phosphine, and boron trifluoride. Today, ION-X® systems provide the semiconductor industry with the first MOF-based sub-atmospheric solution for dopant gas delivery, with proven thermal and long-term stability that exceeds the demanding industry requirements.

Purity

MOFs provide significant advantages in storage capacity and gas purity

As the semiconductor industry continues to face emissions challenges, technologies that aid in the reduction of the negative impact of hazardous chemicals are widely being sought out and adopted.

Compared with traditional materials, MOFs enable greater selectivity, leading to selective adsorption of dopant gases with less affinity for impurities and a more environmentally friendly separation process.

Performance

Maximize gas capacity and minimize cylinder changeouts

Product Features

The ION-X® technology platform enables IC manufacturers to meet the industry’s demanding performance requirements.

Features include:

- Storage and delivery of hazardous chemicals, using state-of-the-art MOF technology as adsorbent

- Delivers ultra high-purity dopant gases at sub-atmospheric pressures

- Selectively adsorbs at sub-atmospheric pressures

- 100% plug and play with existing implant machines

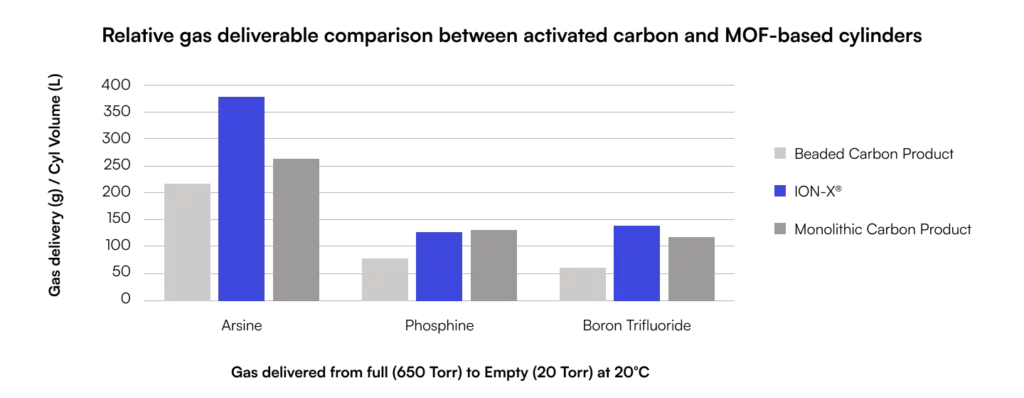

- Delivers capacity premium to Monolithic Carbon Products with AsH3 and BF3

- Favorable desorption and flow characteristics supporting ease of gas extraction

- Reduced change-outs and cost-of-ownership

- Superior cylinder construction with the least failure modes

Trusted Globally

Trusted by Tier 1 semiconductor customers in all major global regions and market segments.

Global Distribution

ION-X® MOFs are manufactured by Numat and distributed globally in ION-X® systems by Merck KGaA, and within the United States and Canada by their affiliate EMD Electronics.

Semiconductor Climate Consortium

Numat is a proud member of the Semiconductor Climate Consortium (SCC).

Together with SEMI and the global semiconductor industry we are working together towards the common goal of creating a more sustainable future.

Formed by SEMI and joined by member companies across the semiconductor value chain, the SCC’s mission is to accelerate the semiconductor industry’s response to the challenge of climate change. Its vision is to accelerate progressive climate action – including support of the Paris Agreement and related accords – with the goal of limiting global warming potential to 1.5°C.

Our PLATFORM

Speed Meets Scale

Our world-class platform integrates MOFs into products and processes, merging chemistry innovation with manufacturing at industrial scale.